A safety valve for gases with integrated sensor technology and communication interface – this innovation from Witt is now available. The gas technology specialist is thus making an important contribution to networking and digitalisation on the valve sector’s journey to Industry 4.0. For the user, this innovation means more transparency and ultimately greater safety when handling gases.

Safety valves are indispensable in gas applications for protecting people, equipment and process integrity from overpressure. Safety valves from Witt are spring-loaded and direct-acting. They automatically release overpressure from vessels, pipelines and equipment before an accident occurs. If the pressure drops below the danger threshold, they close again automatically.

Sensor supplies real-time data

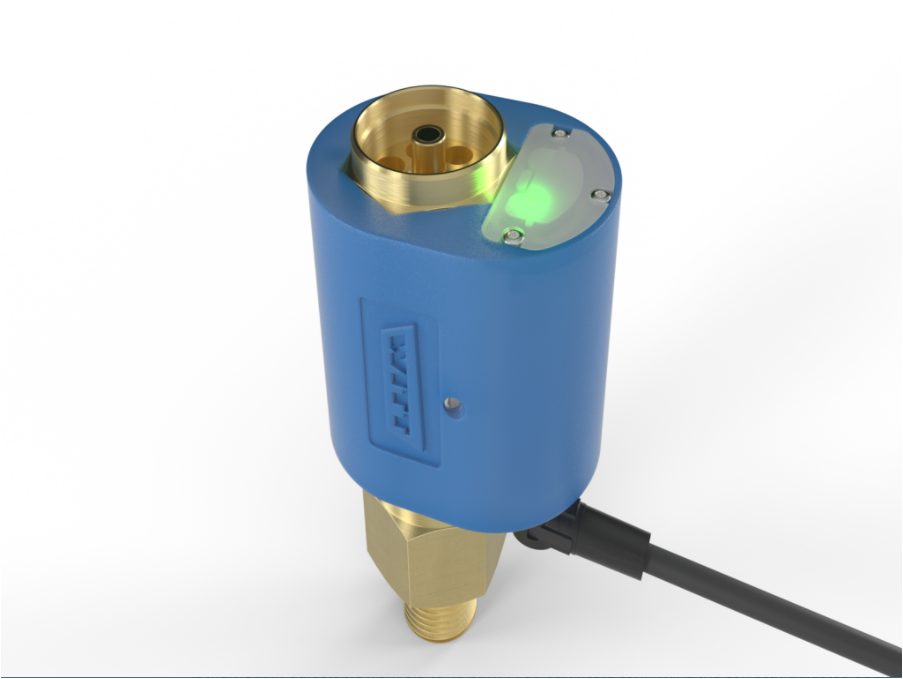

The new, smart valves can do even more: The status of the valve is continuously monitored by integrated sensors and communicated via optical and digital signals. Witt has accommodated the smart function extremely compactly in a box which is firmly connected to the fitting. If the valve opens, this is indicated immediately, optically by a red/green diode directly on the valve and digitally by an NPN/PNP Open Collector signal.

The user can be notified every time there is a demand on the valve, and is thus informed of process deviations. This transparency enables early intervention and significantly increases the safety level of the plant.

Individual opening pressure with TÜV certificate

The new SV805 Smart can be used for all technical gases and is available in brass or stainless steel. The opening pressure is individually adjustable from 0.5 to 45 bar. A TÜV certificate confirming the correctly adjusted opening pressure is supplied by the manufacturer. The permissible temperature range is -30 °C to +60 °C. The component is mounted in any position. The SV805 Smart conforms to the Pressure Equipment Directive 2014/68/EU, category III, module B and D.

“Witt safety valves do their job with the utmost reliability, but in some cases may go unnoticed. With the signaling that is now possible, the user knows at all times whether critical pressures are occurring in the system and can react accordingly,” says sales manager Andrew Smart, underlining the importance of the new functionality. “In this case, more information means more safety”.

“This is the same valve of which tens of thousands are in service world-wide, but now with this super feature” he adds.

But more information is not only valuable for troubleshooting. The smart Witt safety valves also provide the necessary data to prove that the system is operating faultlessly and therefore safely in the long term. This can be very interesting for insurers, for example.

Components for industry 4.0

Market observers agree: smart components for gas installations are here to stay. The benefits are undeniable, particularly their ability to communicate in real-time, with the resultant safety and quality benefits. This historical digital gap in “Industry 4.0” system is now filled by Witt

As an innovation leader in the field of gas technology, Witt launched a project some time ago to digitise safety technology for gas plants. First-class industrial valves with integrated high-tech sensor technology and electronic components – that is the concept of WITT 4.0. In addition to safety valves, other product groups are gradually being raised to the next technical level in this way. For example, the Witt dome pressure regulators, which can already detect and communicate gas pressures, temperatures and flow rates in real time.